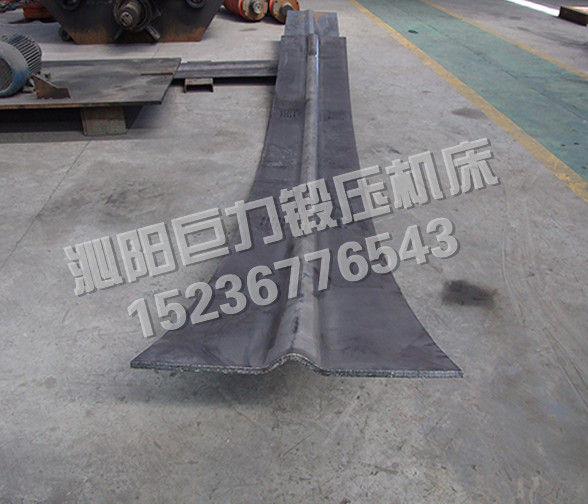

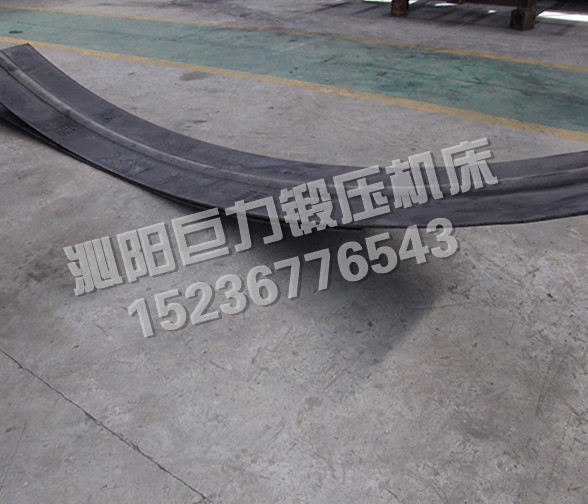

W22NC NC arc forming machine for donkey head can realize rolling forming of sheet reinforcement ribs and pre-bending of both ends at one feeding, and roll it into arc workpiece, and roughly flatten the sheet metal.

It is widely used in petroleum, shipbuilding, chemical industry, machinery, metal structure and other general equipment.

The upper roller of the machine is mainly driven roll, and the alignment roller is also the driving roller. The lower roller and side roller are passive rollers. Down roll, side roll and alignment roll are lifted and lowered by hydraulic transmission. The lifting displacement is controlled by PLC and automatically leveled. The screen digital display shows that the synchronization precision is not more than (+0.2 mm). Mobile independent operation platform is available for mobile operation at any time.

The machine has complete functions, high precision, easy to remove and change rollers, easy to operate, is an ideal arc-shaped plate forming and rolling equipment for donkey head.

The mechanical parts of the main machine of the NC arc plate forming machine are all fixed on the same base, which not only facilitates the installation of the equipment, but also effectively guarantees the geometric accuracy of the machine.

The main machine part includes upper roller part, lower roller part, side roller part, alignment roller part, frame part and so on.

The mechanical auxiliary part includes: hydraulic transverse feeding platform (feeding steel plate), electromagnetic sucker feeding part, feeding roller table part, left and right supporting roller table part, plate alignment part, discharging roller table part, electromagnetic sucker feeding part, hydraulic transverse feeding platform (delivering finished product).