Note: the main technical parameters are as follows:

The working capacity of the coiler is determined by four main parameters: the thickness of the coiler (pre-bending thickness), the width of the coiler, the material quality of the coiled sheet and the diameter of the drum. The conversion relationship between the four parameters in the work, that is, the conversion relationship between the working capacity of the machine, is described in the random instruction for ease of use. Households use equipment more reasonably.

Three, product structure overview

W11BF-Series hydraulic micro-control three-roll corrugated sheet winding machine can complete the end of the sheet metal pre-bending and winding forming, the remaining straight edge is small, is an ideal equipment for rolling round, arc workpiece. The upper working roll of the machine is the main driving roll, driven by hydraulic motor and planetary reducer, the lower and side rolls are passive rollers, the lower and side rolls are lifted and lowered by hydraulic transmission, the lifting displacement is controlled by computer, and the automatic leveling is realized. The screen digital display shows that the synchronization precision is (+0.15mm). The overturn and reset of the overturn bearing body are driven by hydraulic pressure, and the tail of the upper roller is equipped with a balancing mechanism, so that the rolled workpiece and the cylinder body can be easily unloaded. It is equipped with a mobile independent operating table, which is convenient for workers to use and a safety interlocking device. The machine has complete functions, high precision and convenient operation. It is an ideal machine for rolling round, arc and conical workpieces in petroleum, chemical, boiler, shipbuilding, hydropower, metal structure and other industries.

1. The basic structure of the machine tool: the machine is mainly composed of frame part, upper roller part, lower roller part, side roller part, overturn bearing body part, main drive part, hydraulic part, electrical part, lubrication part, basic part and so on. The left and right stands of the machine are mounted on a whole base, forming the main body of the machine. The left end bearing body of the upper roller is mounted in the reverse bearing body, and the right end bearing body is arranged in the right frame. The upper roller is the main driving roller, and the upper working roller rotates; the lower roller cylinder and the side roller cylinder are respectively installed in the guide groove of the left and right frame. The reciprocating movement of the cylinder can make the lower roller and the side roller move up and down the guide groove, and can also be inclined to make the conical workpiece rolled and convenient for the correction and rounding of the workpiece. On the left stand, there is a rollover bearing body. After the workpiece is rolled, the bearing body is turned over and the workpiece is turned over. The movement of work roll is guided by high quality linear slide rail.

2. the inverted bearing body (inverted head) is equipped with a dumping cylinder, which can be dumped and erected to facilitate the workpiece reclaiming. The turning and resetting of the overturning bearing body should have interlocking device. After the overturning of the bearing body, other actions are on standby. Only after the overturning bearing body is reset can it resume action and play a safe and protective role.

3. The lower roll lifting and the side roll inclining lifting are driven by hydraulic pressure, and can be inclined at one end, and can be lifted and lowered at the same time under the inclined state, which is advantageous to the rolling of conical workpiece.

4. the upper end of the upper roller is provided with a balancing mechanism for unloading the rolled workpiece and cylinder body conveniently.

5. Work roll bearings are made of domestic high-quality brand products or internationally renowned brands of low-speed, heavy-load adjusting roller bearings. Lubrication of machine side roller guide adopts centralized lubrication.

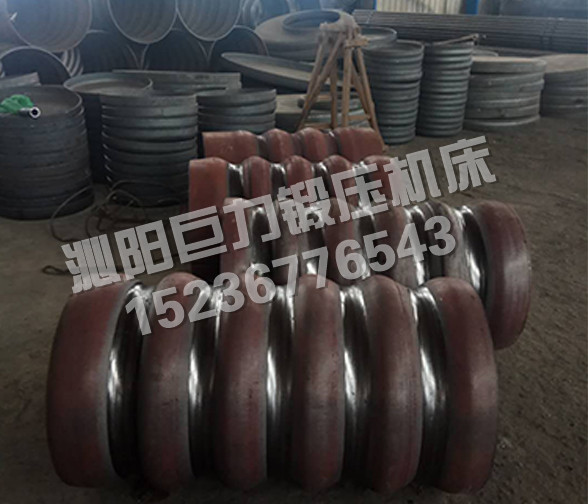

6. The work roll is forged, tempered and tempered, HB260-290, manufactured in strict accordance with the standard process requirements of the work roll. The bearing of work roller end adopts rolling bearing, which has large load capacity and low friction loss.

7. The base and the frame are welded, welded, annealed, processed and manufactured strictly according to the technological standards, and aging treatment is carried out to ensure that the work of the machine has sufficient strength and stiffness under full load and normal work under full load. The strength and stiffness values are all higher than the relevant standard requirements.

8. after the plate is fed into the bending machine, the side roller can be used to realize the positive function of the plate. Rough leveling of steel plates.

9. The machine is equipped with a movable operating table, which is convenient for the operator to use. The touch screen shows the position of the work roll, so that the operator can see clearly.

10. The high-precision sensor controlled by computer can automatically leveling the lower roll and the side roll tilting and lifting displacement. The screen digital display shows that the synchronization precision is<0.15mm.

11. the pre bending residual straight edges are small, which can be used to calibrate the cylinders of various defects.